LoRaWan Street Light Maintenance Standard

GERERAL INTRODUCTION

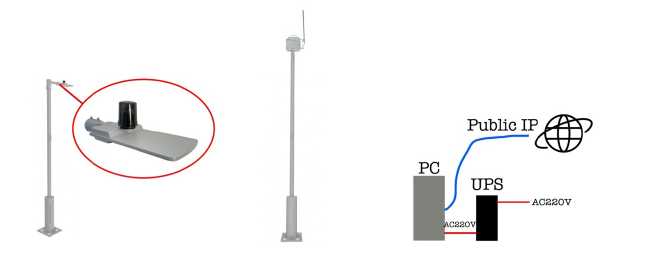

The equipment consists of lamps, light poles, and CMS systems.

Lamp

This street light features: LED light source, die-cast aluminum housing, adjustable arm mounting angle, AC100-277V operating voltage, 20KV surge protection, IP66, 4000K color temperature, Meanwell power supply, and UKCA certificate.

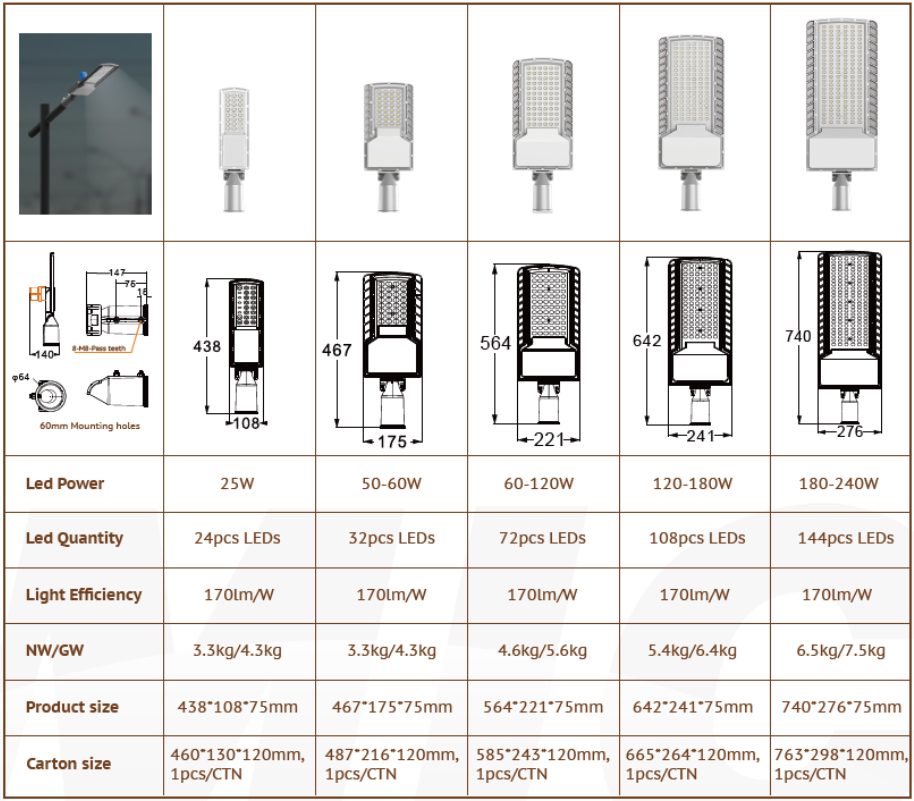

The lamp power used in this project is: 26W, 55W, 71W, 122W, 153W, 198W. Lamp data corresponding to different power:

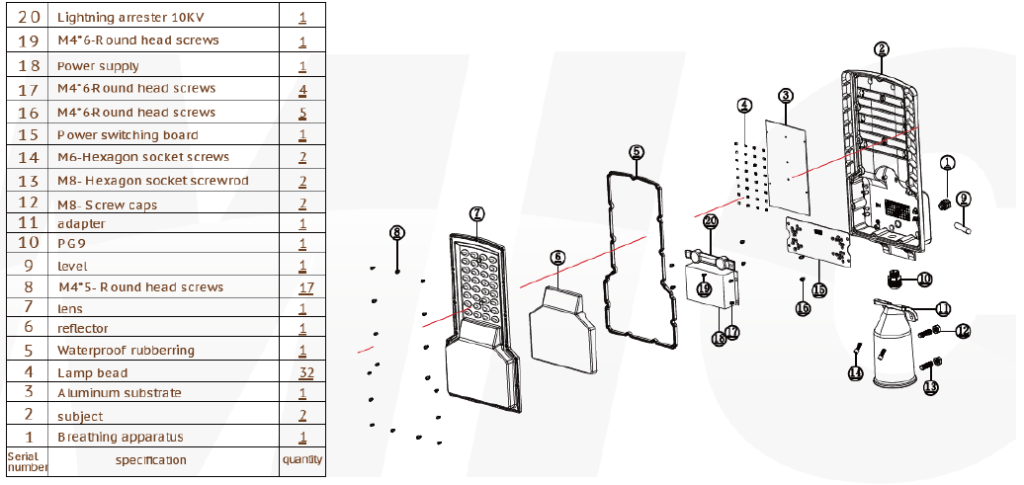

The composition of the lamp structure diagram, different power is only different size, most of the

structure is the same

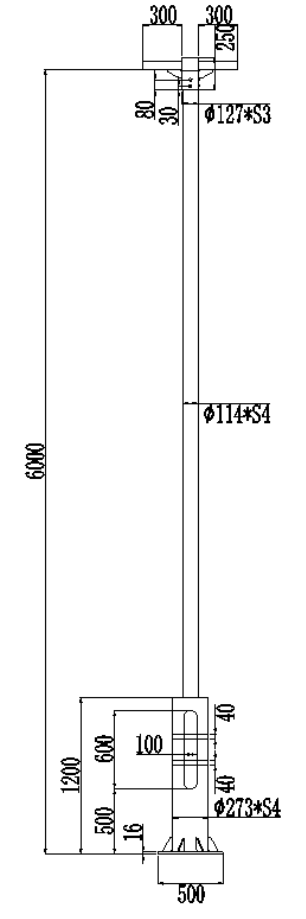

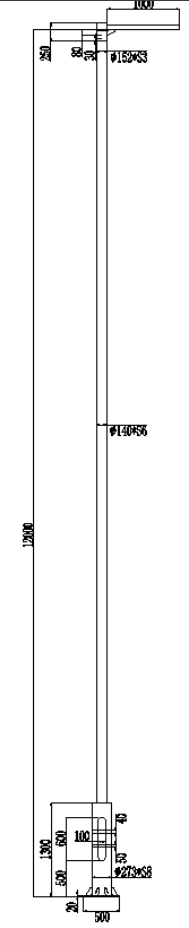

lamppost

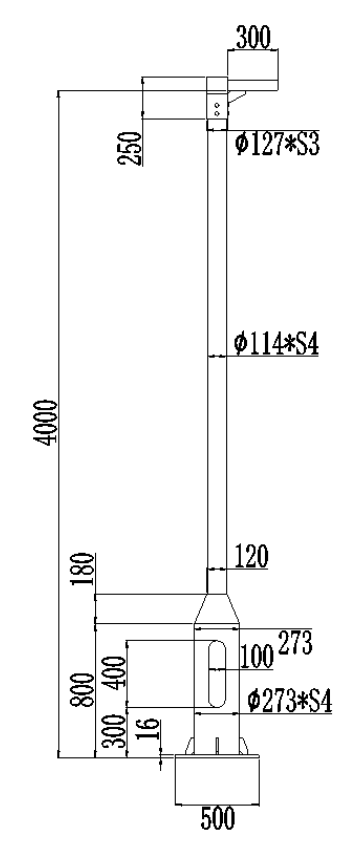

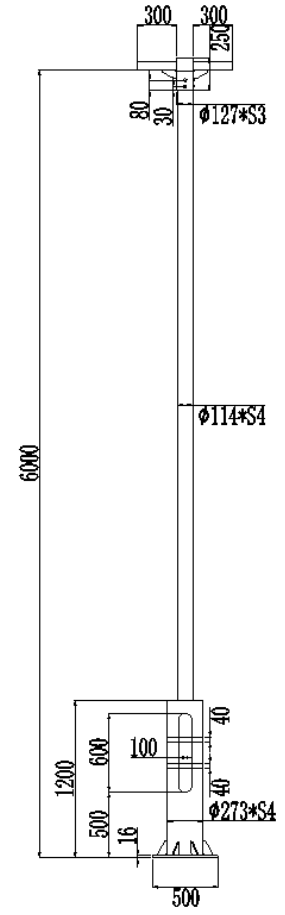

There are 4 heights of light poles, and the light arms have single-arm, double-arm, and high-low arm structures. Light poles are equipped with access doors at the bottom, and are made of Q235 stainless steel, hot-dip galvanized, and sprayed with anticorrosive technology.

|

|

|

|

| 4M light pole | 6M light pole | 10M light pole | 12M light pole |

For more drawing information, please contact the manufacturer.

CMS

CMS is mainly composed of terminal nodes, sensors, gateways, servers, and UPS.

The gateway, server, and UPS use AC100-270V voltage input, and the power input of the server is provided by the UPS.

The gateway should be installed on a high place, such as the roof, or the top of a light pole, and take lightning protection measures.

There is a SIM card installation slot inside the gateway for long-term use, and SIM card communication is more convenient (you need to purchase a local SIM card and open 4G Internet access function)

The server needs a fixed IP address for network access.

The terminal node is the street light controller

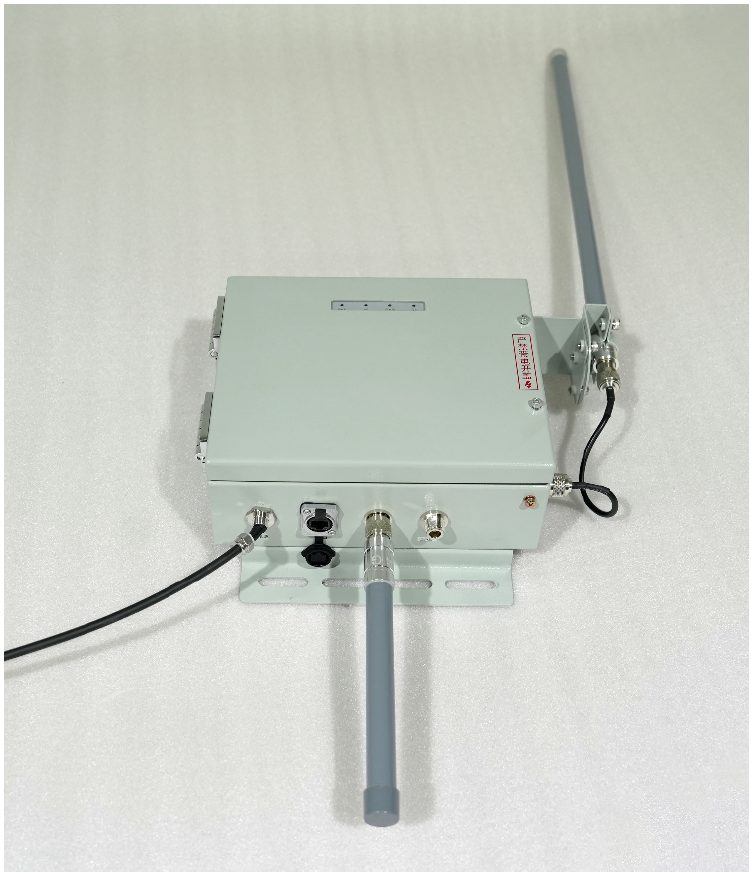

Gateway

As the information converter of LoRaWAN communication system, it is responsible for connecting the communication function of the network server and the terminal node. Support 4G communication, also support network access, support mains power supply, pole, wall and other deployment modes. The gateway is equipped with a hoop, which can be installed on the top of the light pole. And take lightning protection measures.

Sensor

Light sensor, mainly detect the outdoor brightness sensor, through the light sense can realize the function of automatically turning off the light at dawn and automatically turning on the light at dark.

PM2.5 sensor , a sensor that detects the air quality, collects information and displays this value in the CMS.

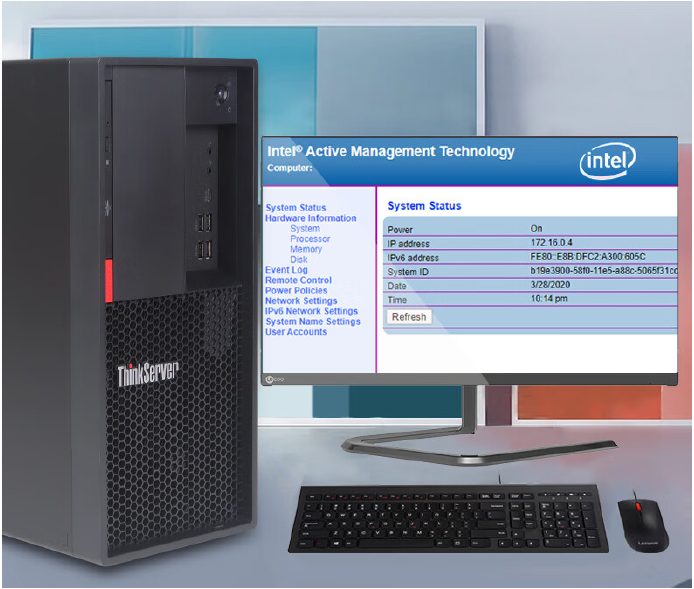

Servers

It is a database, and the street lamp control mode needs to be realized by sending instructions through the server. Shut down the server, streetlight can’t change the control scheme.

The network cable used by the server must be connected to the network with a fixed IP address. If the IP address changes, the CMS communication fails.

UPS

The UPS is an uninterruptible power supply to ensure continuous power supply in the event of a power outage. It uses Huawei 36AH batteries with energy storage to provide continuous power for servers within six hours of a power outage.

INSTALLATION INSTRUCTIONS

- Street light installation, determine the type of light pole to be installed, the power of the lamp head, and then installed, and then get the light pole, the lamp pole internal wires, junction boxes, etc. have been installed, only need to put the lamp pole’s support arm set into the lamp pole, and then the power cord of the street light head, and the lamp pole internal wires connected, and then locking the lamp head screws can be.

- The light pole, use the crane to fix the light pole, then lift the light pole, put the base part downward, after determining the direction of the maintenance door, then lift the light pole to the fixed bolts on the foundation, twist the direction well, then slowly put the light pole into the bolts, and then use the spacer and the nut to twist it in, through the nuts under the 4 bolts, adjust the verticality of the light pole and then lock the nuts.

- The terminal node is connected to the special seat above the light head with anti-dull design, insert the three pins on the terminal into the base and twist it clockwise;

- And the gateway, first put the SIM card into the card slot inside the gateway, then close the cover, put the hoop through the fixed feet of the gateway, then install it to the top of the light pole, then lock the hoop. And take good lightning protection measures.

- The input cable of the server is plugged into the output socket of the UPS, and the UPS is then connected to the utility socket, and the server is connected to the network with a fixed IP address prepared in advance.

The above is the physical product installation diagram of the street light control system.

CMS Operating Instructions

The CMS Operating manual can be contacted for more comprehensive content

Since the operation section is more detailed, you can refer to the vendor’s operation documentation.

The main common operations are listed as follows:

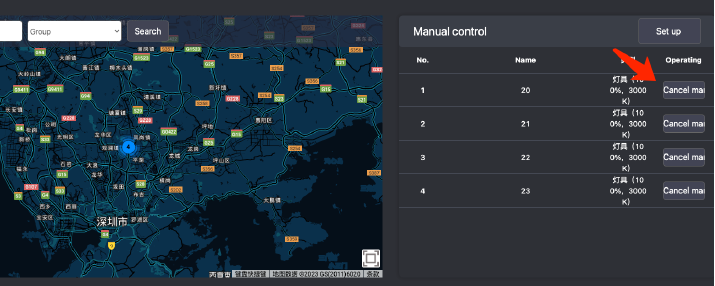

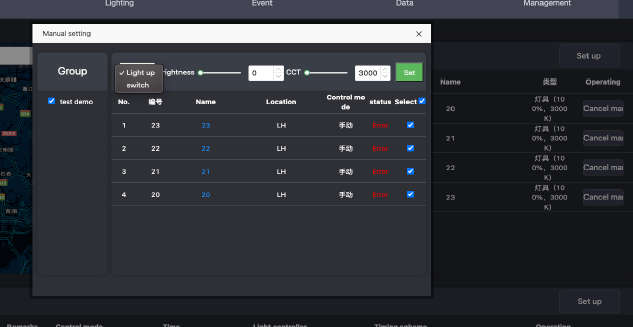

3.2.2 Set the parameters Manually

Select the lamp, slide the brightness and color temperature bar to adjust, Click “set”and “confirm”, it will pop-up window showed “set successfully”.

3.2.3 Restore:

Click the “cancel manual” to restore, the previous lamp execution status.(Only for the automatic control state before)

3.2.4 Manually control the switch of the control cabinet: click the manual setting button to switch the lamp control by cabinet, control by turned on or off.

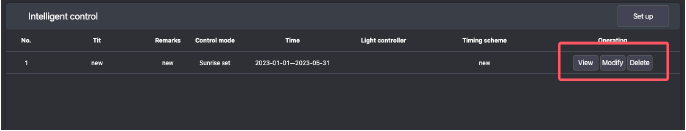

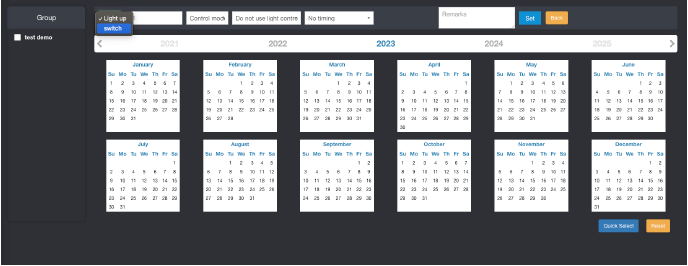

3.3 Intelligent Control

3.3.1 View chat:You can check the control tasks, modify, and delete status.

3.3.2 Intelligent Setting : Add New tasks

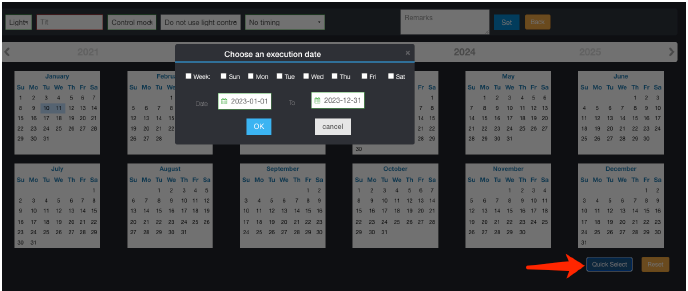

3.3.3 Steps:Select the “Switch”or “Light Up”–>Fill in the task title–>Choose control method–>Choose sensor–>Choose Timing –>Remark important information–>Choose execution time–>Choose group–>Done

3.3.4 Control method description:

(a)Latitude and longitude control:Automatically set up time of lighting turn on/ off(cabinet turn on/off switch), according to local latitude and longitude sunset and sunrise. Lighting system default settings brightness and color temperature. PIR sensor can be used during the day ( invalid during night), Timing control can be executed at night ( invalid during day).

(b)Timing control:Perform dimming and color adjustment according to the timing setting. If there is no task, it will be turned off by default. PIR Sensor execution time is non-timing time.

(c)External control:The control lamps are automatically controlled by on-site laser engraving or other types of sensors, and the light sensor has priority. The light sensor is not executed during the time sequence, and external control is performed during the non-sequence period.

3.3.5 You can not enable use sensor or timing control, they are not necessary execution conditions.

3.3.6 The timing setting is the default setting of the system, which is directly pick up here.

3.3.7 You can quickly set up time to choose hot key at the right corner of system.

3.3.8 The intelligent control list can be multi-task in parallel, principle is that the latter instruction overwrites the previous one.

ROUTINE MAINTENANCE

Work Preparation

Maintenance (work) responsible persons, technicians and others on-site investigation.

The person responsible for the work determines the operators, defines the task, and discloses the operation procedures and safety precautions.

Maintenance tools and labor protection clothing should be arranged by the responsible person and staff selfcheck and mutual check before starting work. The person responsible for the work shall check whether the workers wear protective products to meet the requirements.

Inspect the maintenance materials to ensure product quality and retain the product quality certificate.

Power Cut and Test

Before maintenance, ensure that all power supplies for the cable are disconnected and the ground cable is properly installed.

It is necessary to check the power again before the overhaul to ensure that the line is not powered before the overhaul.

A specialist must take care of the power transmission device.

At least two persons work in a group, monitor each other, and determine the safety of the line before climbing.

Maintenance Process

Maintenance of lamp pole

Whether the rod body is tilted, hit, whether the rod base is sunk or deformed, whether the base and anchor screws are stable, if any of the above conditions, should be dealt with immediately and reported floor by floor.

It is strictly prohibited to attach billboards or banners to lampposts without permission. Once found, they must be removed.

Test the ground resistance of the metal pole every twelve months, and the ground resistance is less than 4 ohms.

If the external paint of the light pole is chipped or rusted, it needs to be replaced or repainted as appropriate.

Whether the fastening bolts of the lamp pole are loose and whether the lamp arm is tilted, tighten the occlusion again according to the situation.

Maintenance of Street Light

Maintenance personnel carry out visual inspection along the road, and if the brightness of the street lamp and the lamp head of the same section of the road are obviously dark or not bright, they should write down the number of the light pole, and then check or replace the street lamp according to the drawing or platform.

During the inspection, if it is found that the light surface of the lamp holder is not vertically illuminated to the road surface, the number of the lamp pole should also be recorded, and the lamp holder should be adjusted, and reported for processing.

Maintenance of Street Light Control System

The server of the control system must be powered by the UPS, and ensure that the UPS works properly. If the power supply of the server or the UPS is abnormal, rectify the fault and report it immediately.

The control system should ensure the smooth access to the Internet. If the network is abnormal or the IP address changes, the self-test of the street lamp will fail and the street lamp will lose control.

During inspection, the location of the gateway should be checked to ensure that the power supply of the gateway is normal, and whether the antenna and lightning rod are normal.

For the SIM card used for gateway networking, it is also necessary to check whether the 4G card package has expired to ensure that the SIM can access the Internet normally.

On the platform, you can also regularly check whether there are street lights that report errors. If there are, the street lights that make errors should be repaired.

Cable Line Inspection and Maintenance

Whether the road surface on the underground cable path is normal, there are excavation marks or not, if there is construction unit construction, should remind attention, and strengthen inspection.

It is not allowed to plant trees, pile heavy objects, discharge chemical wastes, gasoline, oil and other flammable materials or bury other items on the cable line.

Check whether the cable is damaged, whether the joint is overheated, corroded, and melted.

The insulation resistance of the low-voltage cable is measured with a 500V dial, and the insulation resistance value must be above 0.5MQ.

COATING PROBLEM HANDLING

For the phenomenon that the thickness of the coating of some lamp poles is not up to standard, we provide a solution to ensure the safe use of the coating within 2-3 years.

During the warranty period, each time the daily inspection of the street lamp, observe the paint condition of the lamp pole, if it is found that some paint discoloration is obvious, or the paint layer is off, the coating inspection is carried out to determine the coating problem and then repair work:

1.Paint preparation

Choose from a local paint store, color number: Ral7004, or supplied by the manufacturer. The paint is prepared according to the method of the specialty store, and the paint can be painted on the cardboard first, and the effect is satisfied after drying.

2. Work coaching

Put on the work clothes, mask, adjust the paint into the spray bottle, fix the lifting platform;

The spray distance is maintained between 20-30CM, and each spray is approximately increased by 15-20um;

Adjust the width of the spray width and the flow rate of the paint;

After the gun is adjusted, test spray with the test port to check whether the effect meets the requirements. Because the light pole has been installed for some time, after the sun irradiation, the paint of the same color is sprayed on, there may be slight error, and the color difference will be consistent with the original paint after 1 month;

Horizontal and vertical alternating spraying method: both horizontal spray once along the surface, and then vertical spray once. Or vertical before horizontal. The paint film thickness of this method is uniform, smooth and beautiful;

Since the paint is increased this time, clean the light pole before spraying. If it is scratched, it needs to be polished with sandpaper, then cleaned and painted again. It is best not to paint more than 4 times at a time.

During operation, the paint should be stirred regularly to avoid precipitation.

3. Strengthen daily maintenance:

Regular inspection: regular inspection of street lamp poles, timely detection of paint damage or rust and other problems.

Timely treatment: For minor paint damage, it should be repaired in time to prevent the expansion of the problem.

Cleaning and maintenance: Regularly clean the light pole, remove dirt and dust, and keep the paint clean.

Note:

Safety first: pay attention to safety during construction, wear protective equipment, and do a good job of protection when working at height Environmental protection construction: Choose environmentally friendly coatings to reduce environmental pollution.