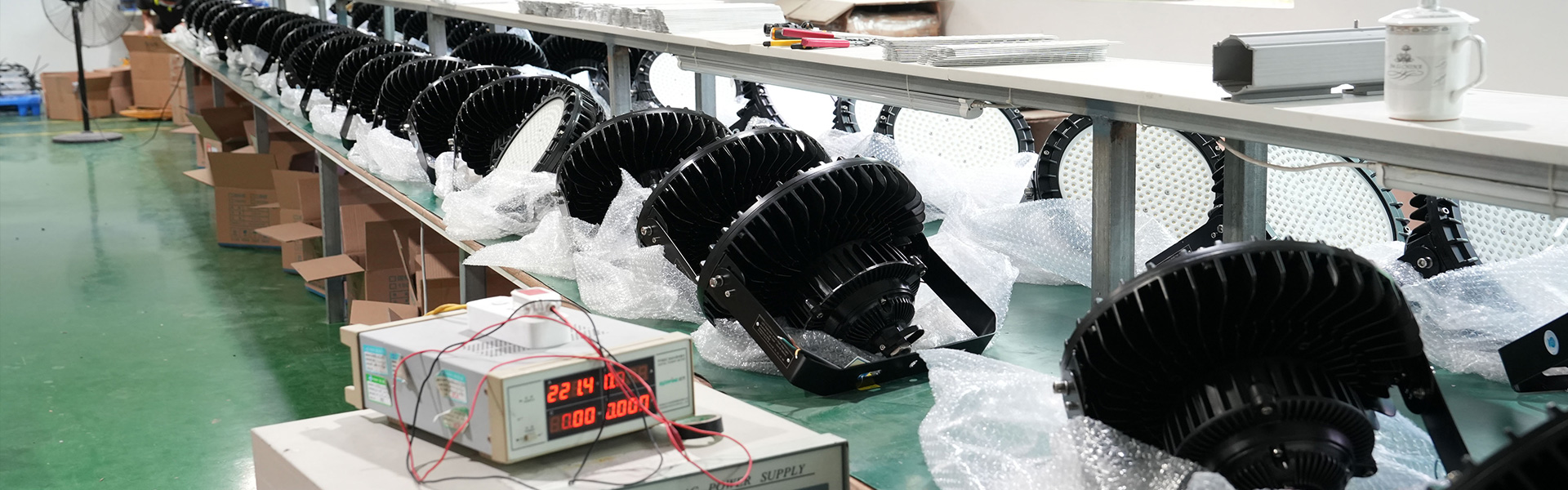

LED Explosion Proof Light

LED Explosion proof light?

LED explosion-proof light is a kind of explosion-proof light. Its principle is the same as that of explosion-proof lamp, except that the light source is LED light source, which refers to various specific measures adopted to prevent the ignition of the surrounding explosive mixture such as explosive gas environment, explosive dust environment, and gas Measures the lamps. LED explosion-proof lamps are the most energy-saving explosion-proof lamps, widely used in oil fields-power plants-chemical plants-petroleum-troops.

Principle

One of the very important explosion-proof principles of LED explosion-proof lights is to limit the temperature of the surface of the shell, the surface of the parts or the surface of the electronic components that are in contact with explosive gases and explosive dust, and to limit the temperature of the electrical contact surface below its minimum ignition temperature or ignition temperature. . LED explosion-proof lights used outdoors need to use waterproof drivers. The led explosion-proof lights used in gas stations need to be shockproof!

Technical advantages

Because LED is a solid-state cold light source, it has the advantages of high electro-optical conversion efficiency, low heat generation, low power consumption, safe and low voltage, long service life, etc., and low energy consumption; therefore, high-power white light LEDs are explosion-proof lamps, especially A very ideal electric light source for portable explosion-proof lamps.

LED explosion-proof lights, patented zone road sealing technology; more in line with the new national explosion-proof technology. It belongs to a kind of electrical equipment used in special industries, which mainly solves lighting problems. It includes a lamp housing, a lamp cover arranged at the front end of the lamp housing, a luminous body and a battery arranged inside the lamp housing, and a switch arranged on the surface of the lamp housing. : The luminous body is a high-power LED module, and a wide voltage input drive circuit is set between the luminous body and the battery; the wide voltage input drive circuit includes a constant current chip, which forms a power module with the battery, and the LED module is connected to On the constant current chip, the power module and the LED module are glued together; the lampshade and the lamp housing are ultrasonically welded.

It uses the characteristics of low heat generation of LED to achieve intrinsically safe explosion-proof, and long life of LED light source; the battery maintains constant brightness at the end of the battery and the end of discharge; a heat sink is installed on the lamp housing to achieve effective heat dissipation of the LED module , To ensure the stability of use, suitable for lighting in various industries such as coal mines, petroleum, railways, and flood control.

It is suitable for hazardous locations in Zone 1 and Zone 2, and explosive gas environment of IIA, IIB and IIC.

It is suitable for hazardous locations in Zone 0 and Zone 21, and explosive atmospheres such as IA, IB, and IC.

Example

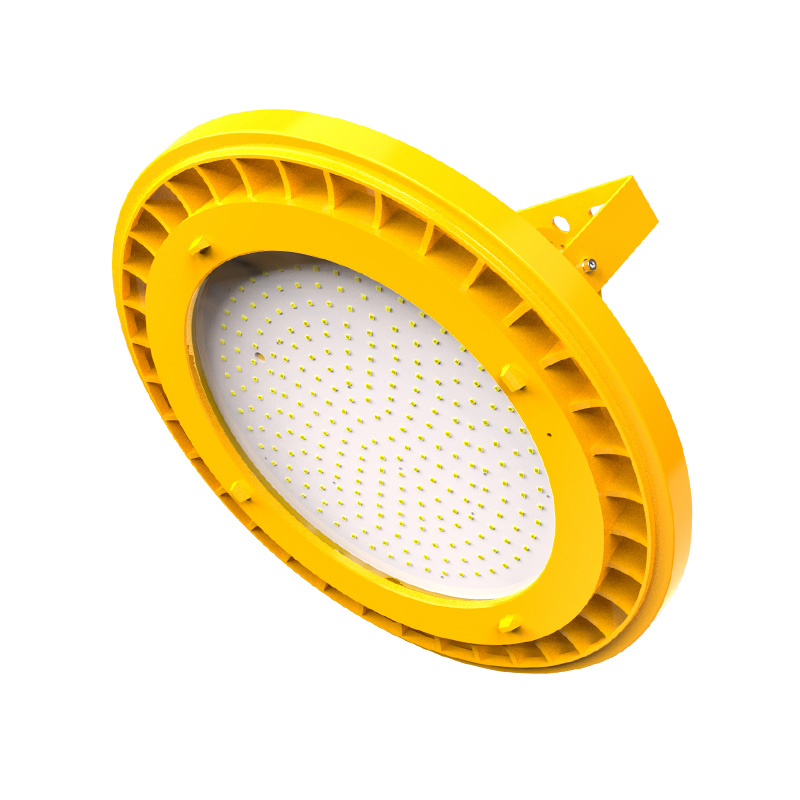

LED explosion-proof platform lights are suitable for fixed lighting in flammable and explosive places such as petrochemical equipment, oil platforms, gas stations, oil pump rooms, transfer stations, oil fields, etc.

Explosion-proof mark: Exd II BT6, Exd II CT4, Gb Protection grade: IP66, IP67.

Performance characteristics

■The light distribution of the lamp is unique, the illuminance of the illumination range is uniform, and the illumination angle is up to 220 degrees, which fully utilizes the light; the light is soft, no glare, does not cause eye fatigue of the operators, and improves work efficiency.

■The light source adopts the brightest LED in the world, and the power consumption is only 40% of the metal halide lamp.

■The key components of the power supply are all selected from the world's top brands, which are efficient and stable.

■Using a unique heat dissipation structure, the use of heat transfer and heat conduction to accelerate heat conduction, effectively ensuring the efficient heat dissipation of the LED, so that the LED life can reach 100,000 hours.

■The explosion-proof type has the highest explosion-proof grade and can be used in flammable and explosive places in various industries.

■Can be connected in parallel, eliminating the junction box and installation costs.

■The shell adopts high-tech surface spraying technology, wear-resistant, corrosion-resistant, waterproof and dustproof, suitable for various harsh environments.

■When the led explosion-proof lamp is used as a floodlight: add a condenser on the surface of the light source to increase the illumination of the floodlight.

■LED explosion-proof lights are used as explosion-proof lights in wineries: they should be designed with road seals; explosion-proof and intrinsically safe; protection grade IP65, anti-corrosion grade WF1, waterproof, dustproof and explosion-proof.

■LED explosion-proof lamp is used as an oilfield explosion-proof lamp: it should be designed with an anti-falling ring; make the oil field derrick vibrate to prevent the lamp from falling off because of the bolts falling off and protected by the anti-falling ring.

■Standard explosion-proof led led that has passed fire inspection and acceptance.

■LED explosion-proof lamp New process aluminum profile stretch forming

Installation and maintenance

Explosion-proof lights should be checked from the nameplate and product manual before installation: explosion-proof type, category, level, group; protection level of the enclosure; installation method and requirements for installation fasteners, etc. The installation of the explosion-proof lamp must ensure a firm fixation, the fastening bolts shall not be replaced at will, and the spring washers shall be complete. The dust-proof and waterproof sealing ring should be placed as it is when installing. Where the cable enters, the cable and the sealing gasket should be closely matched, the cross section of the cable should be round, and the surface of the sheath should not have defects such as unevenness. Excess inlets must be sealed according to the explosion-proof type, coated with 201 replacement anti-rust oil, and tighten the compression nut to seal the inlets. For led explosion-proof lights where there is strong vibration, use anti-falling rings to prevent the lights from falling off.

Precautions

1. Regularly eliminate dust and dirt on the shell of explosion-proof lamps, and improve the light efficiency and heat dissipation performance of the lamps. The cleaning method can be sprayed with water (above the shade on the lamp) or wiped with a damp cloth according to the protective ability of the lamp housing. When cleaning with water spray, the power supply should be cut off, and it is strictly prohibited to wipe the plastic shell (transparent part) of the lamp with a dry cloth to prevent static electricity.

2. Check whether the transparent parts have been impacted by foreign objects, whether the protective net is loose, desoldering, corrosion, etc. If so, stop using it and repair and replace it in time.

3. If the light source is damaged, turn off the light in time and notify you to replace it, so as to avoid long-term abnormal state of electrical components such as ballast due to the failure of the light source to start.

4. If there is water in the lamp cavity of the lamp used in a humid environment, it should be removed in time, and the sealing part should be replaced to ensure the protective performance of the shell.

5. When opening the lampshade, you should open the cover after disconnecting the power supply according to the requirements of the warning sign.

6. After opening the cover, check whether the flameproof joint surface is intact, whether the rubber seal is hard or sticky, whether the wire insulation layer is green and carbonized, whether the insulation and electrical components are deformed and scorched. If these problems are found, they should be repaired and replaced in time.

7. Before closing the cover, use a damp cloth (not too wet) to gently wipe the light return and transparent parts of the lamp to improve the light efficiency of the lamp. A thin layer of 204-1 replacement anti-rust oil should be applied to the flameproof joint surface. When closing the cover, pay attention to whether the sealing ring plays a sealing role in the original position.

8. The sealed part of the lamp should not be disassembled and opened frequently. Patent zone road sealing technology; more in line with national explosion-proof new technology.