مصباح أنبوبي LED

MIC LED tube Light

Manufacturers use semiconductor material to make LED tube light. It is a new type A high-efficiency solid-state light source that emits light with weak electrical energy.

The main features of LED tubes are: long life, low energy consumption, high color rendering, easy maintenance, physical

Small product, DC drive, low drive voltage, fast lighting speed, no flicker, glare Less light, strong shock resistance, less heat, explosion-proof (no high-pressure components), etc. It is one of the most promising high-tech fields in the world in recent years.

LED tube Light parameters

تدفق مضيئة:

The total amount of light emitted by the luminous body per second, in lumens (LM).

Light intensity

Generally speaking, light rays are emitted in different directions with different intensities. The light intensity is the emitting of the intensity of visible light in a specific direction. It is called and the unit-candela (cd)

Illuminance

Illuminance is the ratio of luminous flux to the illuminated surface, in units-Lux (Lux). The luminous flux of 1 Lux with an illuminance of 1 LM is evenly distributed in an area of one square meter.

Luminous decay

LED luminous decay means that after a period of time when the LED is lit, its light intensity will be lower than the original light intensity, and the lower part is the LED's luminous decay.

Stroboscopic

The change of the luminous flux of the electric light source with the alternating voltage cycle is called stroboscopic. Studies have shown that stroboscopic is the main cause of myopia and migraine.

Luminous efficiency: represents the efficiency of the light source converting the consumed electrical energy into light, unit-lumens per watt (LM/W)

Color rendering index

It is a quantitative description of the color rendering of the light source, and the symbol is Ra. The degree to which the light source presents the color of an object is called color rendering, that is, the degree of color fidelity. The light source with high color rendering shows better to the object, and the colors we see are closer to the natural primary color; low color rendering.

The light source has poor color reproducibility, and the color deviation we see is also large. The International Commission on Illumination (CIE) sets the color rendering index of the sun as Ra=100, and the color rendering index of various light sources is different. Color rendering is a very important parameter in lighting design, which directly affects the true color effect of the illuminated object.

Average life

Refers to the number of hours when 50% of a batch of LED lights are damaged, unit-hour (H)

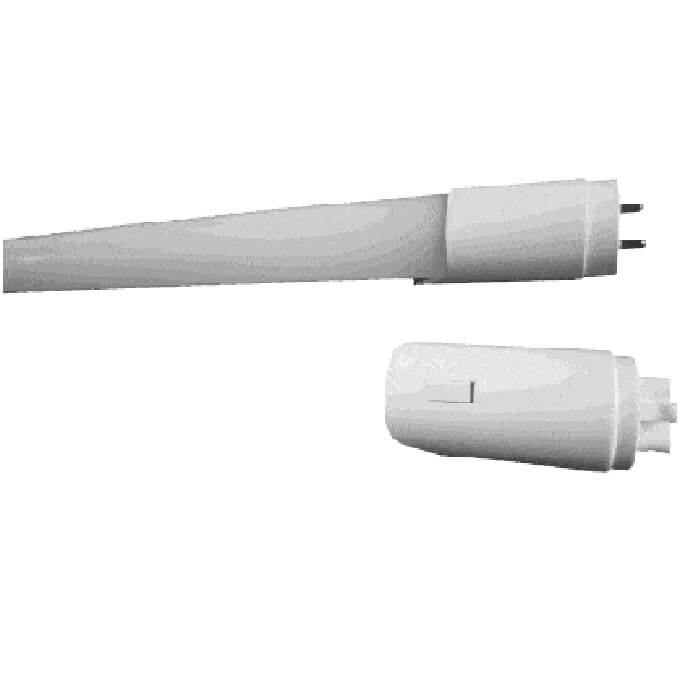

LED tube light structure

Manufacturers use tube shell, plug, lamp beads, circuit board, and power supply to compose the LED tube light. It is possible to dismantle each part. Also, you can repair or replace any damaged part. Recycling of LED material is also an option. Utilization is a more environmentally friendly lighting product.

LED tube light is the fourth generation of new cold light source. The main mission is to replace the existing fluorescent lamp. Therefore, its structure and size are the same as the current fluorescent lamp. Commonly used lamps are rated according to the diameter of the tube, such as T5, T8, T9, T10, etc., and T is the abbreviation of tube, which means tubular lamps, which are ordinary fluorescent tubes. Each T is 1/8 inch (inch). T8 tubes are tubes with a tube diameter of one inch.

The lengths of commonly used lamps are 0.6m, 0.9m, 1.2m, 1.5m, etc.

Classification and characteristics of common driving power supplies for LED lamps

General LED can only be driven by direct current, and no alternating current or voltage can be applied to both ends of the LED. At the same time, in order to obtain high-quality lighting effects and make the LED output stable and long-life luminous flux, the input current of the LED must be constant. However, the existing power supply system usually uses 120V or 220V alternating current. Since it is not possible to directly power the LED via AC so to make the LED work normally and stably, you need to add the AC-DC conversion power supply in the front. The conversion power supply widely used in LED tubes is divided into:

Non-isolated constant current power supply

Non-isolated means that there is a direct connection between the load end and the input end, so there is a danger of electric shock when touching the load, because the non-isolated power supply will introduce the high voltage of the AC power supply to the load end, causing Risk of electric shock.

Usually the insulation between the LED and the aluminum radiator is also dependent on the thin film insulation of the printed board of the aluminum substrate. Although this insulating layer can withstand the high voltage of 2000V, sometimes the burr of the screw hole will cause the so-called creepage phenomenon. So there is a huge hidden danger in safety.

Isolated constant current power supply

Isolated type refers to the isolation transformer between the input end and the output end. This transformer may be power frequency or high frequency. But it can isolate the input and output. It is possible to avoid the risk of electric shock.

Since the isolated switching power supply has an absolute advantage in electrical safety, it is widely used in the field of LED lighting. However, because the isolated switching power supply has an additional transformer than the non-isolated power supply, and the volume of the transformer is relatively large. Therefore, The built-in isolated power supply for LED lamps is restricted by cost and space

Material and characteristics of LED fluorescent lamp board

1. Glass fiber board (FR4)

Manufacturers use a glass fiber cloth to make glass fiber board. The mechanical properties, dimensional stability, and impact and humidity resistance are relatively high. Its electrical performance is excellent, the working temperature is high, and the environment affects its performance.

The environmental impact is small. Compared with aluminum substrate, its cost is lower than aluminum substrate, but it is far inferior to aluminum in terms of heat dissipation Substrate.

2. Aluminum substrate

Aluminum substrate is a unique metal-based copper clad laminate, which has good thermal conductivity and electrical insulation

Can not compare with the mechanical processing performance of fiberglass board.

LED tube structure design

LED tubes are all PC tubes, mainly because For the early LED lamp drive power supply, non-isolated electricity was used. Power source, in order to prevent the driving power from leaking through the shell, use PC Tube, the lamp bead used is Φ5DIP straw hat lamp bead, which will soon. It was found that the light decay of this lamp is very serious, mainly due to heat dissipation.

The problem is that all the tube blocks all the heat within itself, thus not allowing it to dissipate. The life of the cap lamp is inherently short, and the use of the lamp is limited.